Rod - Stainless Steel 416 Rod - Pinstock

416 Stainless steel round pin/rod stock.

Used for bolsters and securing handle material. This 416 comes in dead soft which is perfect for peening as it tends to work harden. Price is per foot.

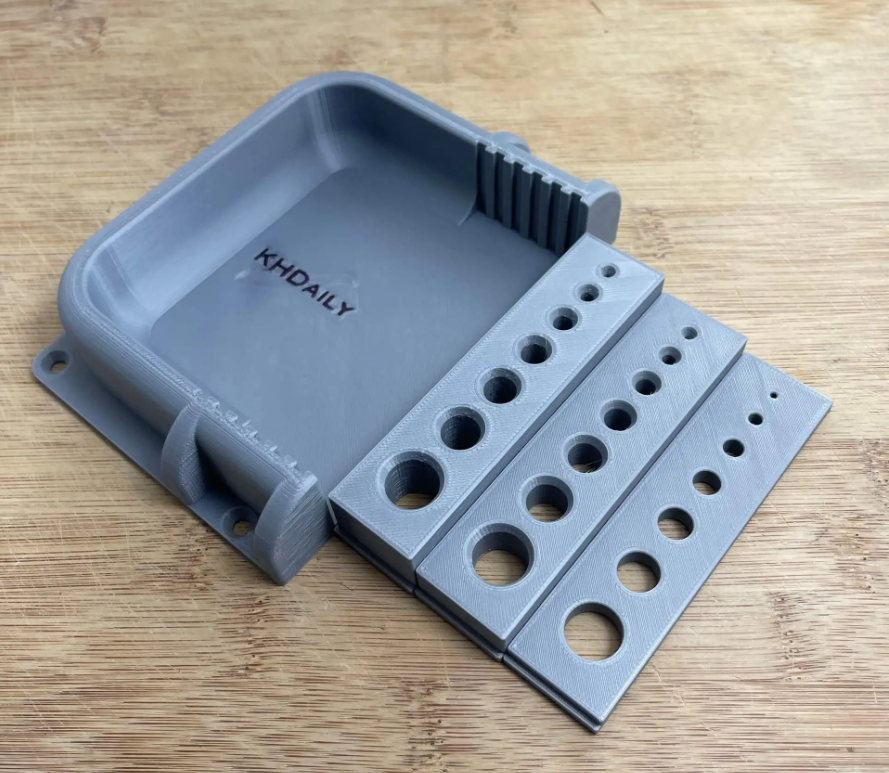

Tip: If you don't want your pins to show in your bolster several things need to happen. Clean the pin stock and the hole both with acetone or alcohol. I give the pins a quick run on the grinder with a 120 or 240 grit belt I use rubbing alcohol since I don't believe it be as toxic as acetone. Use a tapered reamer 2/0 for 1/16" through 1/8" for pinning your bolsters. This gives a place for the pin stock to expand and blend in as you peen it. Slightly crown the pins. The pins should sit proud of the bolster surfaces (both sides) at their diameter. When you peen it, peen it as far along as you can. Check the bolster alignment from the top and bottom, they tend to move a little if the holes have some play. Make sure they are flush. I use a needle nose vice grip to snug the bolsters up if they don't get flush to the tang. When you have them peened and mushroomed well, smash the hell out of it to get it to blend with your 416 bolsters. I use 3lb maul to finish the job. Lately, I've been using a pin press you can see it here. The pin press seems to be more elegant and a LOT quieter when I'm working in the basement shop late at night.