Mother Of Pearl and Other Acrylic

-

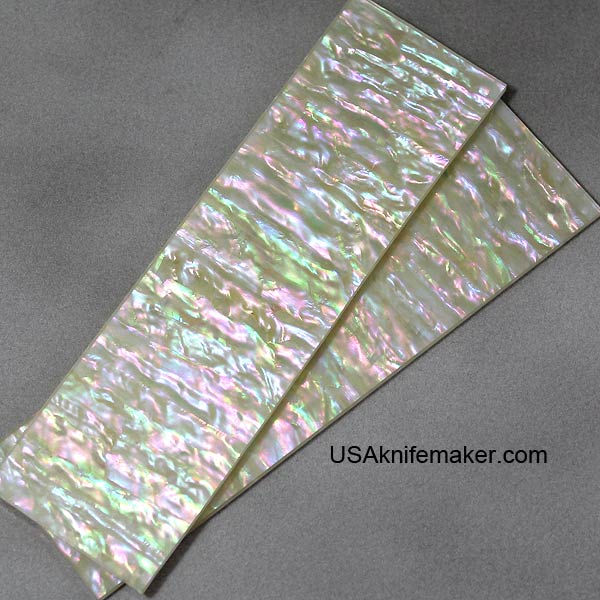

ALVS - Awabi Ribbon Shell White Backing 3/16" Scales - Knife Handle MaterialSKU: HM-ALVS-103$35.16

ALVS - Awabi Ribbon Shell White Backing 3/16" Scales - Knife Handle MaterialSKU: HM-ALVS-103$35.16 -

ALVS - G.A. Shell Select Green Tint Top Green Backing 1/8" Scales - Knife Handle MaterialSKU: HM-ALVS-305$26.64

ALVS - G.A. Shell Select Green Tint Top Green Backing 1/8" Scales - Knife Handle MaterialSKU: HM-ALVS-305$26.64 -

ALVS - G.A. Shell Select with Red Tint Top and Red Backing 1/8" Scales - Knife Handle MaterialSKU: HM-ALVS-306$26.64

ALVS - G.A. Shell Select with Red Tint Top and Red Backing 1/8" Scales - Knife Handle MaterialSKU: HM-ALVS-306$26.64 -

ALVS Paua Shell Blue Tint Top and Blue Backing 1/8" Scales - Knife Handle MaterialSKU: HM-ALVS-405$26.64

ALVS Paua Shell Blue Tint Top and Blue Backing 1/8" Scales - Knife Handle MaterialSKU: HM-ALVS-405$26.64

Mother of Pearl

Mother Of Pearl isnt pearl material at all. It is a shell of various species that is cut into various shapes and admired for its brilliant reflective colors and nearly translucent 3 dimensional appearance. Since it is from a shell, its use in knife handles requires it to be flattened by sanding or grinding. You will see sanding or grinding marks on flat MOP knife scales. These sanding marks are removed the same way they are from wood, by using progressively smaller grit sand paper. The pieces are small and this process goes fairly quickly but you should expect to have to work on the face of the MOP to remove sanding marks. I wouldnt bother with removing the sanding marks on the back side. The MOP can take a little polishing with the buffer and some white compound. Any other color compound may stain the material.

Pay attention to the thickness of the MOP you are buying. Thicker is better since it is stronger and gives you more depth of material to work with to remove any scratches. Potato chip thin MOP is going to be very fragile and frustrating to work.

Drilling this material can be a test of nerves but it shouldnt be. Its just not that hard. Always use a sharp bit and take your time. Use as little pressure as possible and have a solid piece of metal or hard wood as a scrap backer to prevent or minimize break out when the drill bit breaks through. Don Cowles sets his drill press stop clamp at the height of the backup piece scrap piece. With the tip of your drill bit just touching the backup scrap piece, set the drill stop so the drill bit cant go any further. Now drill your MOP slowly with a sharp bit and a bit of mineral oil or cutting lube. (The UltraLube we sell is fantastic cutting lubricant that is largely mineral oil.) When the drill press hits stop, turn the MOP piece over. Your drill bit tip should have just barely broken the surface of the MOP with a bit of a bump. Finish drilling your hole where this little bump is sticking out. Basically, you are drilling the same hole half way from both directions. You should have very little, if any, break out using this technique.

If you have worked with bone, stag or ivory you will find working with MOP a snap. You drill, shape, sand and polish MOP using the same tools and techniques as you would with these other natural materials. There isnt any reason to be scare of the stuff.

When putting pins in this material, make sure the holes are over sized for the pin. You do NOT want a snug fit or you will crack the MOP. Maybe it wont crack today, but it will eventually. Think of all the old ivory or bone handled knives you have seen that have cracks around the pins. This is from a press fit pin that eventually cracked the material. I guarantee the knife maker at the time didnt send out a knife with a crack around the pin. It happened years later from natural movement. You can put a bit of superglue in the hole to fill it in and keep the dirt out. Superglue has just enough flex in it to not create stress and eventually crack the material.

There is quite a difference of opinion as to how safe MOP dust is or not. Some argue that it is not at all a risk as it is inert, some argue it as risky as silica dust when inhaled. The best advice may be to error on the side of caution and wear a respirator when grinding or sanding this material and raising dust.

When grinding or sanding any natural material, it tends to move. Keep the heat down when using power tools or your piece will warp and when you try to grind or sand. If you are trying to make a piece flat, getting it hot will just have you chasing it until the piece is sanded away as it will cool off and change back to its true shape. If it is too hot to touch to your lips, you are working it too hot.

Grading is less about appearance than it is about how many flaws are present in that size piece. Most MOP looks fantastic and has great iridescence and a lot of chatoyant luster. Generally, the more flaws there are in a piece of MOP, the cheaper it is. Most flaws can be worked around as the shell cutters have learned to put these toward the edges or be stuck with slabs of MOP no one wants. Certainly some MOP has different texture and appearance but grading that is impossible. The other generality about MOP is the larger the piece, the more expensive it is. Shells only grow so big!

Our Grading Scale

Presentation Grade: There will be no flaws of any significance on the front or back. You should expect no discoloration, chips, fractures, worm holes or other defects. There may be an occasional very fine micro chip or two along an edge. These will be very small if present at all. We have very high standards for this grade and believe you will be very pleased with this quality of scale. These have been inspected twice on every surface. They have been hand paired with another scale that has similar appearance in the 3 dimensional texture of the material.

A+ Grade: The front of the scale will be nearly perfect as in presentation grade. There may be a combination of some chips on the back along with minor discoloration on the back on one of the edges. The front of scale is 100% usable but there may be some flaws on the back to work around or to fill in on the edges. The typical flaw in this grade is some edge chipping from the cutting saw. This is a very good set of scales and is appropriate for all but the very most high end knives.

A Grade: The front of the scale will be very good for +95% of the surface. It is important to emphasize the front will be very good and only a small portion of the front may have a flaw. There may be some edge chipping on the front near one or both of the ends. The chips will be small but visible. These can be worked around and would normally be trimmed away. There may be some discoloration from the back that has leaked to the front on one of the edges. They may be some evidence of fracturing but the scale has been manually twisted and pressed and has proven to be solid. There may be a worm hole that can be worked around, but this is rare for this grade. The worm hole would have to be at or very near the edge. This is a very economical grade to work with and will have exceptional appeal if you cut a smaller piece out of the full size scale. If you want Presentation grade appearance at a great price, buy a larger, lower grade scale and cut out the best part to use.

B Grade: The front side will be 90% plus. This is the working mans selection. You can expect a good looking piece of MOP but you should also expect to have to trim some waste away to get it. There will probably be some chips to fill in the back and maybe some small chips on the front to cut around. Its fine looking material, you just have to work through around some flaws and maybe fill in some voids on the back. If you are new to MOP, try this first. It will be great looking stuff, I guarantee you that, you will just have to trim it out.