Evenheat Kiln free shipping includes shipping cost, residential fees, and potential liftgate service fees within the contiguous United States. Free shipping will be based on Standard UPS and Motor Freight. Any form of expedited shipping will be paid by the customer. Shipping for replacement parts or upgraded parts after purchase will be paid for by the customer.

To be clear contiguous United States excludes shipping to Alaska and Hawaii. Orders being sent outside the contiguous United States our Internationally the customer will be subject to all shipping cost.

IMPORTANT NOTES ON ORDERING:Evenheat Kiln Free Shipping Terms

Outside the lower 48 When checking out, the shipping charges in the shopping cart will not be accurate! To find out the shipping you can contact us via email. Please send us your full shipping address, the oven you would like to purchase, and the best way to contact you. We will get the shipping quote from Evenheat and get back to you. Or you can call us at 507-720-6063 and we will get a quote for you. |

Custom Mode ProgrammingDevelop your own heat treating programs using the Custom Mode. Custom Mode allows you to determine your specific temperature rates, set points and hold times. Custom Mode Programming offers 12 individual programs. Each of the 12 programs allows for up to 32 segments. All On-the-Fly features such as adding time and temperature to holds and skipping ahead are available. 12 Custom Mode ProgramsThe Rampmaster allows the heat treater to save up to 12 Custom Mode programs in memory. Your programs remain in these 12 locations indefinitely and can be recalled for use or modification at any time. Numerical Keypad for Data EntryOne reason the Rampmaster is preferred over the Set-Pro for heat treating is its numerical keypad. Simply key in your data. Upgraded Alarm Features - New for 2010We have updated our Alarm features in 2010 to include two new alarms that help you to be at the oven when you need to be. Beginning of Process Alarm - The Beginning of Process alarm alerts you when the oven temperature has reached the process temperature soak/hold period. The process temperature soak/hold is where your heat treating takes place. For those who like to load the oven at this point, this alarm was made just for you. End of Process Alarm - The End of Process alarm alerts you when the process temperature soak/hold period has ended and it's time to remove the material for quenching or further processing. This is a very critical point and this alarm lets you know when to act. General Temperature Alarm - The Rampmaster also features a general temperature alarm. This alarm feature allows you to determine the temperature when the alarm sounds. View Segment FeatureWhile running, the Rampmaster displays the basic information of current temperature and time. It does not display your program settings. Doing so would be overwhelming and confusing, and that's not good. However, there are times during a program when this information must be known and View feature does just that. A simple press of a key is all it takes to see what the Rampmaster is up to. Back KeyThe BACK key has a very simple function: it takes you back to what you were viewing previously. It's helpful during programming to check previously entered data and it comes in handy when going through various Menu options. Just press it to go back! 32 Segments per Program: The Rampmaster allows you to use up to 32 segments for each Custom Mode program. Add Time to Hold While RunningIt's possible to add additional temperature to a programmed hold temperature. The ADD TEMP feature increases the hold temperature by 5° (factory default) with every press of the ADD TEMP key. Like the Add Time feature, the Add Temp feature uses a dedicated, single function key to make use easy and anxiety-free. Suspend the ProgramThe Suspend feature works much like the Add Time feature, but with a twist: you may suspend the program (cause the temperature to hold) at any point in the program, not just at the programmed hold point. The suspend feature temporarily interrupts the program and holds at the currently displayed temperature. Once the suspend is canceled, or times out, the program begins where it left off. It essentially lets you "buy some time" at any point in the heat treating process. More FeaturesThe Rampmaster 3 has many more features including a delayed start, PC compatibility, error diagnostics, and many related menus and viewing options. |

TAPThe TAP Controller features a touchscreen design that offers a large screen with full text. All commands and menu items are legible, easy to read and easy to operate. Simply respond to the screen with a touch! The TAP Controller is supplied pre-loaded with firing schedules as well as allowing the artist to create and store their own custom programs. On-the-fly features such as adding time to hold, adding temperature to hold and skipping ahead are available and easy to use. The TAP Controller allows for Wi-Fi connection via our well-placed USB and Ethernet ports. This connectivity allows the artist to monitor the kiln, develop and edit programs and perform TAP Controller functions from a networked computer, tablet or mobile device. WiFi Dongle Add-On Touchscreen technology offers many improvements and Evenheat is dedicated to providing this technology to our customers. |

|

|

All Information Displayed on One Screen: Because the TAP Controller offers a fairly large display screen it is possible to display all firing information on one screen, in full text, while firing. There's no need to touch the screen and go looking. The display will show your current firing segment or step, current kiln chamber temperature, the current programmed rate per hour and hold time. It's all there at one time and on one screen. We love this feature as it tells us exactly where we are in the firing without having to touch the control. The Display from a Distance: While programming and using the TAP Controller, screen information is presented in a legible and easy to understand text and font size. While sitting at the Standby position or when running a firing schedule the TAP Controller screen changes to a large font, high contrast display which is easily seen from across the studio or workspace. Near or far, the TAP display has you covered. Running a Pre-loaded or Stored Firing Schedule: The TAP Controller is supplied with pre-loaded firing schedules that differ depending upon the style of kiln. Currently, we offer pre-loaded glass, ceramic and metal clay firing schedules (programs). All of our pre-loaded firing schedules have been developed professionally on Evenheat equipment. Custom Mode Programming: Feel free to develop your own, custom programs. The TAP Controller makes it very easy and understandable. All firing data is shown on the touchscreen as you develop which makes it very easy to keep your place and not get lost in the process. Your firing data will be shown in a table format and is entirely legible and understandable. This full-text feature of the TAP Controller is one of its highlights. All information is available to the eye. The TAP Controller contains a vast amount of memory and there is no practical limit to the number of programs you wish to create and store. There is also no practical limit on the number of available segments or steps used for a firing schedule. You're free to create exactly what you want. Modifying Firing Schedules: Firing schedules (programs), whether pre-loaded or custom, are sometimes not exactly to your liking or needs. The TAP Controller allows you to modify or edit any stored program more to your liking. Simply choose to edit the firing schedule and make the changes. Wi-Fi Capability: The TAP Controller is designed for computer networking via USB Wi-Fi or Ethernet connections. This connectivity allows the artist to monitor the kiln, develop and edit programs and perform TAP Controller functions from a network connected computer, tablet or other mobile devices. WiFi Dongle Add-On Add Time to Hold While Firing: During firing, it's not uncommon that additional hold time may be needed to achieve the desired results. The TAP responds to this desire by allowing you to add any amount of time to the Hold while in progress. Add Temperature to a Hold While Firing: During firing, it's not uncommon to add to the set point temperature to achieve the desired results. The TAP responds to this desire by allowing you to change the set point temperature while the Hold is in progress. Skipping Ahead to the Next Segment: You'll find moments while firing when you would like to stop the process and skip ahead to the next available segment or step (very common in glass firing). The TAP Controller offers a single touch feature that allows just for this. It's called Skip Ahead. The Skip Ahead feature does what it sounds like: it skips ahead to the next segment. With glass firing, the segment or step right after the fusing or slumping operation is the anneal, which is exactly where you want to go. It's a great feature that allows you to make the glass you want to make. Accessible USB and Ethernet Ports: Evenheat has designed our TAP Controller package for instant, direct access to the USB and Ethernet ports. There's no need to disassemble the kiln to access these ports. These ports are readily accessible from the outside of the Controller package, simply plug in and go. Proper design and execution, it's what you expect and get from Evenheat. Cost per Firing: The TAP Controller monitors many functions, among them is your actual cost per firing. Simply enter your cost per kilowatt hour and the wattage of your kiln. The TAP Controller uses this information to calculate a realistic approximation of the cost of your electrical usage for your firing schedules. Graphing: During firing the TAP Controller collects the kiln chamber temperature and creates a visual graph that can be seen with a single touch of the screen. The graph is continually updated every minute for the duration of the firing. This allows the artist to monitor the history of the firing as it takes place. The visual graph is also stored in memory, along with the particular firing data and can be recalled and inspected at any time. Software Updates: Software updates will be available on a semi-annual or as-needed basis and are downloaded to the TAP Controller via a USB thumb drive, Wi-Fi connection or Ethernet connection. Updating is fast and simple and will give you the latest in features, themes, and functionality. Diagnostics: Diagnostics provide a real-time look into the usage of critical kiln components. From the diagnostics screen, you can view the actual number of relay actuations, the amount of time the heating elements have been on, and the amount of time the thermocouples have been exposed to high temperatures. Logs: The TAP Controller stores all functions and user keystrokes into various logs. These logs become valuable for viewing previous firing graphs, error events, and programming functions. |

Evenheat KO 27 Heat Treat Oven Solid State Relay

| - LOWEST PRICE GUARANTEED! | |

|

These are shipped directly from Evenheat. |

|

More Info |

|

Evenheat KO 27 Heat Treat Oven |

Evenheat KO 27 Heat Treat Oven – Ultimate Capacity and Precision for Large and Production Heat Treating

The Evenheat KO 27 Heat Treat Oven is the deepest model in the KO Series, designed for professionals who need maximum interior space for larger or longer workpieces. With an internal size of 27" deep, this oven is ideal for production runs or heat treating long blades, tools, and larger parts, making it perfect for high-volume work.

Built for both durability and convenience, the KO 27 features a swing-out door and cool-touch handle, providing safe, easy access to your workpieces even during extended heat treating sessions. The full stainless steel jacket and corner-mounted hardware are designed for strength and long-term reliability, ensuring the oven can handle continuous, heavy-duty use.

The KO 27 is equipped with three controller options: the Set-Pro, Rampmaster, or TAP Controller. Whether you need simple, straightforward control or advanced programmability, these controllers provide precise temperature management, ramping, and hold time functionality, ensuring excellent results for hardening, tempering, and annealing.

Specifications:

- 9” W x 5.5” H x 27” D

- 126 lbs shipping weight

- 240 volts, 15 amps, 3600 watts, NEMA 6-20

- Max temp on the KO series ovens is 2400F

Features:

- Solid State Relay

- Access Port (Pat. Pending)

- Cool-touch handle

- Excellent temperature distribution

- Full stainless jacket

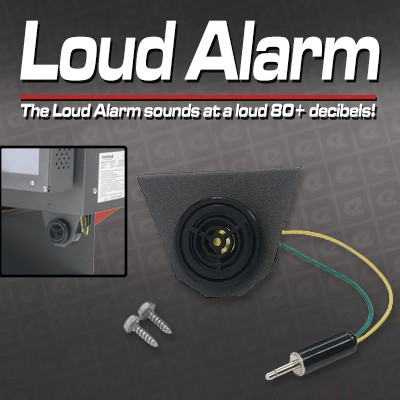

- Loud Alarm Output Jack (Rampmaster, & TAP)

- Multiple Control Options (Icon, Rampmaster, & TAP)

- Responsive thermocouples

- Side-opening Door

- Swing View Adjustable Control

Controllers:(click below for more information)

Options: (click below for more information)

- Loud Alarm Option

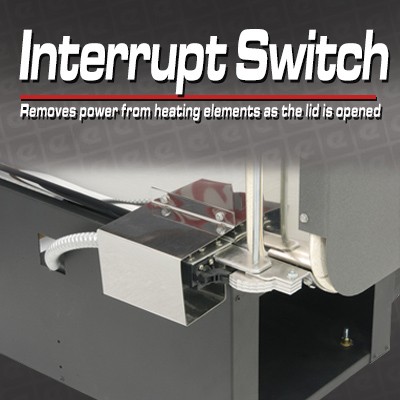

- Power Interrupt Switch

- Quiet Drive Solid State - INCLUDED

- WiFi Is now included on New Ovens with the Icon, and TAP Controller

Accessories: (click below for more information)

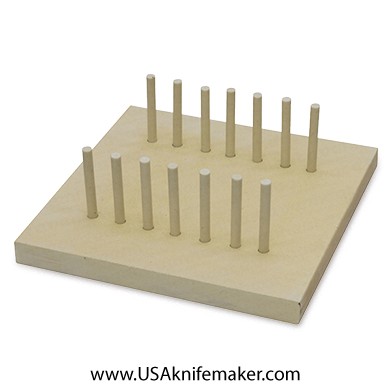

- Knife Dogs Blade Fixture - 4.5" W x 5.9" D

- Evenheat MK 1 Blade Fixture - 5 1/4" x 5 1/4"

- Evenheat MK 2 Blade Fixture - 7 1/4" x 7 1/4"

Options & Accessories

Wifi Add-On - TAP Controller OnlyWi-Fi is now included to establish a Wi-Fi Internet connection for the TAP control. WiFi Dongle Setup Instructions The TAP control in this oven now has Wi-Fi built in for Internet access. This connectivity allows the artist to monitor the kiln, develop and edit programs and perform TAP Controller functions from a networked computer, tablet or mobile device. |

- Customer Service

- Contact Us

- FAQ

- Privacy Policy

- Shipping & Return Policy

- Terms of Use

- Ordering

- My Account

- Gift Cards

- View Cart

- Download Catalog

(507) 720-6063

info@usaknifemaker.com

2650 9th Avenue

Mankato, MN 56001