HotShot Knife Oven HS-360K - 6" x 6" x 10" - 2200°F

HotShot HS‑360K Knife Heat Treat Oven – Compact Power for Professional Results

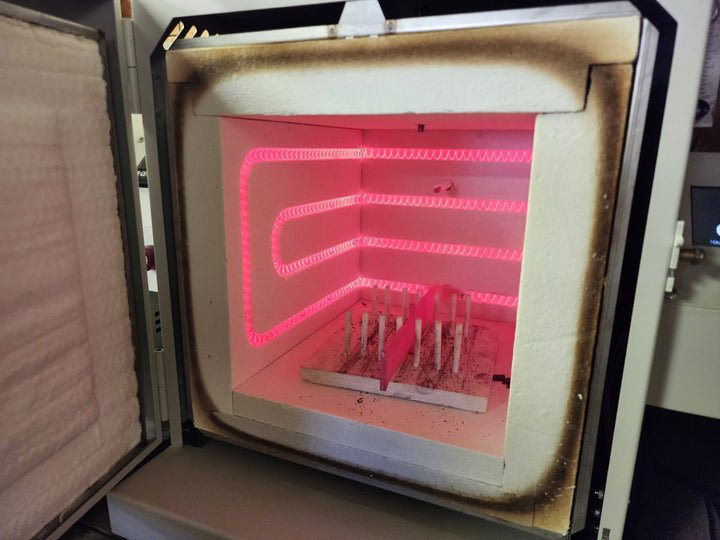

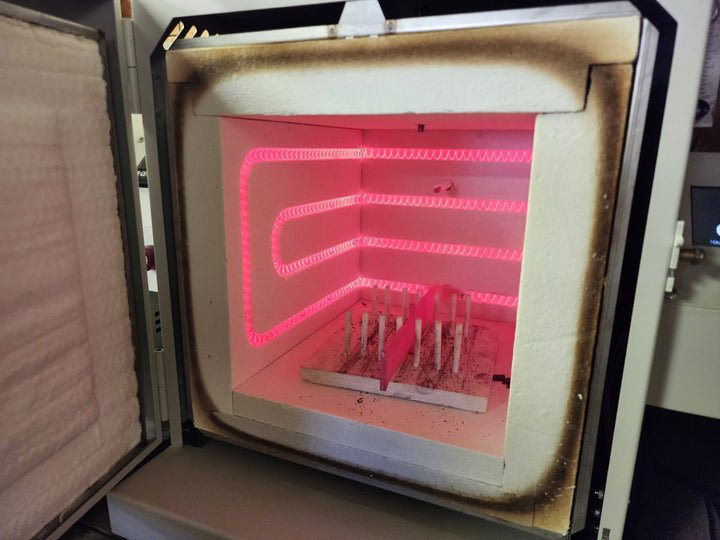

The HotShot HS‑360K is a compact, high-performance heat treat oven designed specifically for knife makers and metalworkers. Reaching temperatures up to 2200°F, this oven is capable of heat treating all common blade steels with precision and consistency.

Available in two power configurations—15-amp/110V for standard outlets or 20-amp/240V for faster, more efficient heating—the HS‑360K is flexible enough to suit any workshop setup. Its small footprint makes it a perfect fit for even the most space-limited shops.

Engineered with Hot Shot's cool-to-touch housing, the HS‑360K sets a new standard for safety in the oven and kiln industry. Whether you’re a hobbyist or professional bladesmith, this U.S.-built unit delivers pro-grade results in a user-friendly package.

Highlights:

-

Max temp: 2200°F – suitable for all knife steels

-

Compact chamber: 6" x 6" x 10"

-

Power options: 110V (15A) or 240V (20A)

-

Cool-to-touch exterior for added safety

-

Built in the USA using premium components

-

Ideal for small shops, garages, or mobile setups

The HotShot HS‑360K brings advanced heat treating capability to anyone, anywhere—without compromising on quality or performance.

STANDARD: Novus Controller

Novus – The N1030T series of PID (proportional–integral–derivative controller) temperature controllers have been designed for non-experienced novice users for combining extreme simplicity in operation with quality performance found in expensive high-end controllers. The Novus N1030T can be operated by simply turning on the oven and setting the temperature needed. Streamlined Design: you do not need to create programs in the 1030T, making it perfect for straightforward heat processing.

UPGRADED CONTROLLERS:

| 15amp/110V | 20amp/240V | |

| Max Temperature | 2200°F | 2200°F |

| Plug Voltage | 110V | 240V |

| Max Amp Draw | 15 Amps | 9 Amps |

| 1-Phase Circuit | 15 Amps | 20 Amps |

| Break-in Period | 4-5 Hours | 4-5 Hours |

| Length of Cord | 6ft | 6ft |

| Weight | 47lbs. | 47lbs. |

| Exterior Dimensions | 20”Lx18.5”Wx16”H | 20”Lx18.5”Wx16”H |

| Interior Dimensions | 10”Dx6”Wx6”H | 10”Dx6”Wx6”H |

| Warranty | 18 Months | 18 Months |

The Perfect Oven For Knife Making

Heat treating knives is done to harden the steel for sufficient use and to not cause any damage or weakness to the knife. Owning your own oven allows you to heat treat on your time and not have to wait for the heat treating facility.

What is heat treating?

Heat treating can improve the strength, durability and reduce wear on material. It is the process of heating metal to a certain temperature, ramping the temperature(s) at a certain rate of time, soaking or holding it at the temperature(s) and then cooling it.

Why heat treat?

The purpose of heat treating is to bring steel to a hardened state. The correct hardness depends on the application of the steel being treated.

Why would I want my own oven to heat treat?

The main reason you would want to do your own heat treating is to save time and money. Heat treating facilities can often be backed up, expensive and require certain size batches of material to be done at one time. Heat treating knives allows the knife to get to a hardness level that will not cause the knife to bend, get damaged or cause any weak parts.

Constructed to last

Hotshot ovens are specifically designed with the end user in mind. Hot Shot ovens feature a full swing side opening door to allow safe and easy insertion and removal of material as well as a cool-to-touch one-handed handle made from high-quality stainless steel for easy opening and closing.

Hot Shot ovens are constructed with a high-quality powder-coated shell. The high-density fiber insulation in a Hot Shot oven is machined to high tolerance specifications so that each piece fits perfectly together to provide a proper seal, ensuring that it will maintain its temperature and work efficiently to prevent loss of heat. Each oven comes with a removable high-density floor. This is ideal to assist with project setup or if it needs to be replaced.

Hot Shot uses Kanthal A1 heating elements, a type K thermocouple and every oven comes standard with a solid state relay at no additional charge.

Advanced Features

Solid State Relay

Unlike many other ovens & kilns all Hot Shot ovens come standard with a solid state relay. Having a solid state relay eliminates the distractive clicking noise that a mechanical relay makes. A solid state relay is also more dependable and provides a longer life expectancy than that of a mechanical relay.

Programmable Alarm

Each unit comes standard with an integrated alarm that can be set to alert the user when a desired point or temperature is reached in the program.

Safety Door Switch

We also have integrated a safety door switch that will de-energize the heating

element when the door is open.

Argon Gas Inlet Flow Meter Kit (Optional)

Argon is usually delivered at dew point less than -75°F with an oxygen content below 20 ppm. This gas provides an inert atmosphere and is suitable for a variety of heat treatment processes.

Annealing (non-ferrous metals, stainless steel, and alloy steel)

Brazing

Sintering

Hot Shot offers this well-designed and easily adaptable Argon kit for all your heat-treating needs. Includes flow meter, tubing, fittings and ceramic dispensing needle.

(Argon gas not included)