Ceramic Glass Platen Liner - for Flat Platen

Write Your Own Review

Ceramic Platen Liner .192" thick

-

This is ceramic fireplace glass.

-

It holds up very well to heat and thermal shock.

-

Use this on your flat platen to provide a very slick, smooth surface for your belt to ride over.

-

This glass will wear much slower than even a hardened steel platen.

NOTE: This glass is not guaranteed against breakage. If you break it, you own all the pieces. Glass breaks and this application will eventually force you to break it to replace it as it wears or it will break from use. Use at your own risk. Buy 2 of them if you think you will break one.

NOTE: There are several pictures of installing this Pyrex below on my own No Weld Grinder platen. Scroll down and click on the pictures.

The friction is much lower so you will generate less heat. There are other variations and trademark names for high temperature glass. Pyraceram(tm) is one. I don't have a list of them all. Regular window glass and safety glass expand too much from the grinding heat and will crack. I've learned this the hard way.

There is an important caution you must be aware of when using Pyrex like this. This is NOT safety glass. If it shatters, it will produce very sharp and dangerous shards of glass. If it comes loose from your platen while grinding, it could be a disaster. Always wear eye protection when grinding.

I have heard of several reports of glass liners coming off during grinding. The heat generated softens the adhesive and the glass gives way. In every case, the glass shattered and threw dangerous pieces of glass. There are plenty of reasons not to use this material on your grinder. Having said all that, I use it and have for years. I think most makers that try it, swear by it. You DO have to be careful when you apply it to your platen.

Review the pictures here of how I mounted a piece of ceramic glass on one of my No Weld Grinder flat platens.

-

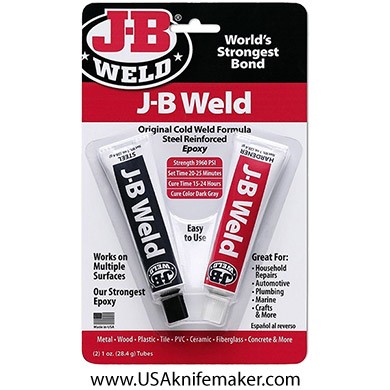

I use JB Weld, (not the quick set version, regular please). It has a higher heat resistance temperature than most other epoxies. Make sure the epoxy you chose can take the high temps of grinding.

-

Don't clamp the glass when gluing it together. The glass will flex and you will put extra stress into the glass holding it in place, with stress, as the adhesive cures. When it heats up, the heat cause it to crack. Use tape to just hold it in place while curing.

-

Create a small ledge for the glass to rest on in case the adhesive comes loose. This little ledge might hold it in place long enough to notice before it comes off in a spray of broken pieces.

-

When using the Pyrex lined platen, expect some static electricity. Maybe a lot of static electricity. I use Static Guard, a spray chemical you use on clothes to eliminate static. It is in the laundry section of most stores. Simply spray the inside of the belt and a little bit around the roller wheels of the grinder. Most of the static will be gone for several grinding sessions.

In the pictures here you will see:

-

Locating the 4-40 screws by eye ball flush along the bottom of the glass. If your glass is too long, grind some off the end just like you would a piece of metal and slightly chamfer the edge. Glass grinds easily. Wear gloves and eye protection though. I used an 8" piece on this 9" platen. The extra metal sticking on on the bottom won't be a factor as the thickness of the glass won't let the belt even touch the extra metal sticking out.

-

I drilled and tapped for the screws. Naturally they weren't level. No problem. Just file the heads a bit until the glass sits level on the screws and is plumb with the edges.

-

Clean both surfaces very well. Acetone is not a good cleaner. It leaves an oily residue. So do most soaps. I use rubbing alcohol. To prove this yourself, rub some of each on your glass and see which one leaves a residue.

-

Goop the JB Weld on the platen and then place the glass on it. You will probably get some air pockets. If they don't easily squeeze out, remove the glass and slather some JB Weld on the dry spots and then place the glass back. You can clean up any the squeezes out but leaving it doesn't hurt a thing.

-

Make sure your glass is aligned with all the edges of your platen.

-

In the picture, I used 4-40 socket heat screws because it was what I had on hand. You can use anything you come up with that you trust for a ledge. If I have to replace this glass, I'll heat it with a torch and peel off the glass, grind it all flush and re-do the process.