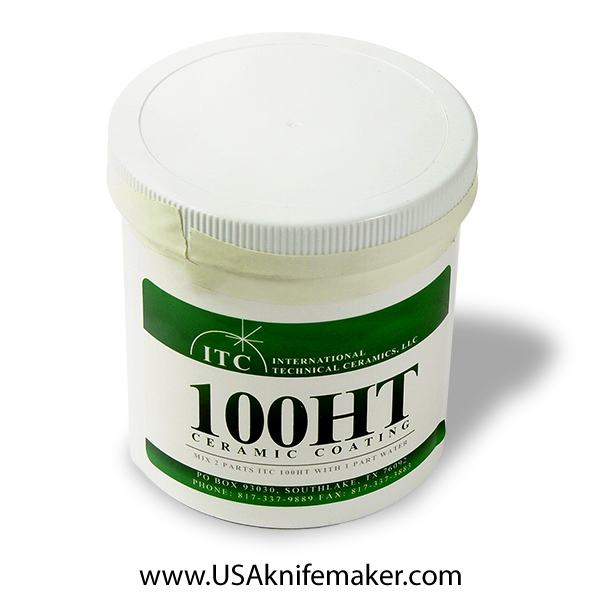

ITC-100HT Ceramic Coating 1 Pint

Out of stock

SKU

FTS-ITC-100HT-1Pint

Shelf Location

T1.5

$49.99

Write Your Own Review

ITC-100HT Ceramic Coating 1 Pint

Our most versitile high temperature coating has proven to achieve outstanding energy avings and refractory protection. Use it alone and as a base coat for other ITC products.

ITC 100 HT and ITC 296A will repair and improve the lifetime of all kiln interiors, including hard brick, insulating fire brick, fibre blanket and fibre board. Use on all kiln furniture such as setters, slabs and pins to minimize galse sticking and on burner blocks and burner tips.

ITC 100 HT is used as the base coat followed by ITC 200 EZ, a patching compound for filling in holes and crevices caused by broken and separated brick. ITC 296A is an optional finishing coat to achieve additions purity and to enhance performance and increase longevity of elements.

These energy-saving materials are easily applied within a matter of hours, and outstanding results are attained. Following are just a few of the benedfits that our customer have reported with the use of ITC Products:

PREPARE SURFACE: Remove all loose and weakened fiber and bricks, debris, particles, dust and grease from the interior walls, door, corwn, floor and grooves behind electrical elements. Immediately before applying ITC 100, dampen these areas by spraying lightly with water.

MIX: To one gallon of ITC 100 and one-half gallon of water and mix well.

APPLY: Spraying is the best method of application. Spray guns are available from ITC. For small applications a brush can be used.

COVERAGE: 500 to 100 sq. ft. per gallon

**Use with other ITC products in order shown on the ITC Problem Solving Chart

Our most versitile high temperature coating has proven to achieve outstanding energy avings and refractory protection. Use it alone and as a base coat for other ITC products.

ITC 100 HT and ITC 296A will repair and improve the lifetime of all kiln interiors, including hard brick, insulating fire brick, fibre blanket and fibre board. Use on all kiln furniture such as setters, slabs and pins to minimize galse sticking and on burner blocks and burner tips.

ITC 100 HT is used as the base coat followed by ITC 200 EZ, a patching compound for filling in holes and crevices caused by broken and separated brick. ITC 296A is an optional finishing coat to achieve additions purity and to enhance performance and increase longevity of elements.

These energy-saving materials are easily applied within a matter of hours, and outstanding results are attained. Following are just a few of the benedfits that our customer have reported with the use of ITC Products:

- SAVE FUEL: Depending upon the extent of repairs, fuel savings can range from 10% to 55%, the average being 35%.

- CUT FIRING TIME: Expect to reduce your firing time, perhaps by several hours.

- IMPROVE QUALITY: Your ware will be better than ever, and seconds due to glaze sticking and kiln dirt will be drastically reduced.

- QUICK PAYBACK: ITC Products pay for themselves in a short period of time, maybe within one or two firings.

PREPARE SURFACE: Remove all loose and weakened fiber and bricks, debris, particles, dust and grease from the interior walls, door, corwn, floor and grooves behind electrical elements. Immediately before applying ITC 100, dampen these areas by spraying lightly with water.

MIX: To one gallon of ITC 100 and one-half gallon of water and mix well.

APPLY: Spraying is the best method of application. Spray guns are available from ITC. For small applications a brush can be used.

COVERAGE: 500 to 100 sq. ft. per gallon

**Use with other ITC products in order shown on the ITC Problem Solving Chart

ITC Problem Solving and Application Chart

| Aluminium Smelters | |

| Repair and maint. brick, fiber and castables in contact with molten aluminium. | ITC-100, 148, 296A |

| Repair and maint. brick, fiber and castables on doors and above molten metal. | ITC-100, 200, 296A |

| Repair and maintain furnace door jambs | ITC-100, 148 |

| Repair and maintain crucibles, pouring ladles and troughs | ITC-100, 148, 296A |

| Minimize dross buildup and carbon deposits on metal | ITC-213, 296A |

| Protect graphite pumps and graphite parts used in molten metals | ITC-213, 100, 296A |

| Protect and prolong thermocouple life | ITC-213, 296A |

| Repair burner blocks | ITC-100, 200 |

| Die Casters | |

| Save fuel | ITC-100, 200, 296A |

| Repair and maintain refractory | ITC-100, 200, 296A |

| Minimize seeding, peeling, chipping, dusting and cracking of refractory | ITC-100, 200, 296A |

| Protect metal utensils such a ladles, skimmers, thermocouples | ITC-213, 296A |

| Repair burner blocks | ITC-100, 200 |

| Steel Foundries | |

| Repair and maintain tundish | ITC-100, 148, 296A |

| Minimize slag buildup on metal equipment | ITC-213, 296A |

| Repair and protect metal molds | ITC-213, 296A |

| Repair and maintain crucibles, ladles and pouring troughs | ITC-100, 148, 296A |

| Prolong electrical element life | ITC-213, 296A |

| Spray coating for sand molds | ITC-213, 296A |

| Forge and Blacksmith | |

| Repair and maintain refractory fiber, castables and brick forge linings | ITC-100, 200 |

| Seal refractory fiber blanket and increase infrared reflectance | ITC-100, 296A |

| Repair and protect burner nozzles and tuyeres | ITC-213, 296A |

| Protect metal ladles, skimmers and pipe crucibles | ITC-213, 100, 296A |

| Coat parts for heat treating | ITC-213, 100 |

| Prevent oxidation of exotic metals | ITC-213 |

| Heat Treaters | |

| Save fuel, improve uniformity of temperature | ITC-100, 200, 296A |

| Repair brick or fiber in furnaces | ITC-100, 200 |

| Prolong electrical element life | ITC-213, 296A |

| Protect fans retorts and other metal parts | ITC-213, 296A |

| Mend cracked steel in ovens | ITC-213, 296A |

| Repair burner blocks | ITC-100, 200 |

| Reduce recovery time | ITC-100, 200, 296A |

| Potters, Artists, Porcelain, Brick and Tile Manufacturers | |

| Save fuel, cut down firing times, improve uniformity of temperature | ITC-100, 200, 296A |

| Repair brick and fiber in kilns | ITC-100, 200 |

| Minimize kiln dirt and improve ware quality | ITC-100, 296A |

| Minimize glaze sticking to shelves and kiln furniture | ITC-100, 296A |

| Prolong electrical element life | ITC-213, 100, 296A |

| Protect metal sand seals on car bottoms and metal burner tips | ITC-213, 296A |

| Repair burner blocks | ITC-100, 200 |

| Power Plants, Paper Mills & Incinerators | |

| Repair and prolong refractory life in furnace area and minimize ash build-up | ITC-100, 148, 296A |

| Protect metal water and steam pipes in boiler area and minimize ash build-up | ITC-213, 296A |

| Repair burner blocks | ITC-100, 200 |

| Gold, Silver & Other Precious Metals | |

| Repair and maintain crucibles and ladles | ITC-100, 148, 296A |

| Repair and maintain graphite equipment and parts | 213, 100, 148, 296A |

| Forge, Furnace and Kiln Construction | |

| Protect metal surfaces, door frames, tuyeers and burner nozzles | ITC-213, 296A |

| Prime metal for application of other refractories | ITC-213 |

| Coating and gluing fibre boards and blankets (Kaowool) | ITC-100 |