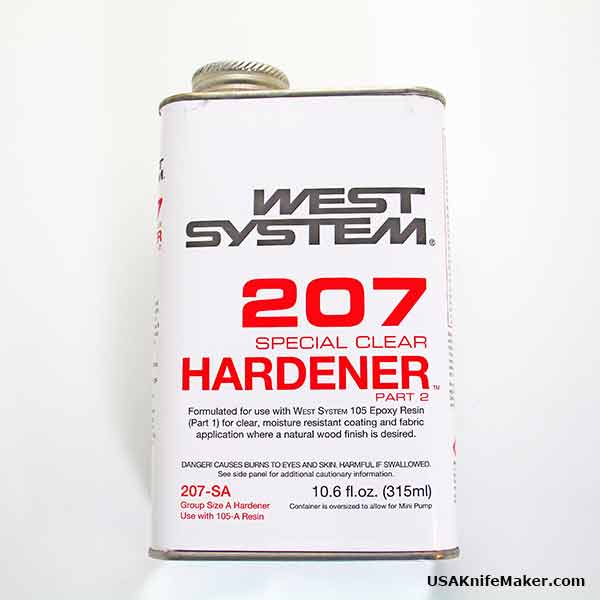

West System - Hardener - Special Clear

Made in the USA

West System Hardener

**NOTE** We can not ship this item internationally

TIP: This hardener is ideal to use when you want to inlay something into a handle and have a clear, tough coating over the top.

207 Special Clear Hardener was developed for coating and fiberglass cloth application where an exceptionally clear, moisture-resistant, natural wood finish is desired. 207 Hardener will not blush or turn cloudy in humid conditions. Thin film applications roll out and tip off smoothly, requiring less sanding in preparation for finish coatings.

Professional and first-time builders like 207 because it is reliable and easy to use. Three coats or more can be applied in one day without additional surface preparation. Fewer coats are required to fill fiberglass weave and in most cases the final coating can be sandd the following day. Boats can be built faster. Builders also appreciate the excellent fiberglass wet-out characteristics achieved with 105/207, yet it won't drain from vertical surfaces like the very slow curing, low-viscosity epoxies.

105/207 has strong physical properties, so it can be used as a structural adhesive for gluing and laminating. It has excellent compatibility with paints and varnishes. An ultraviolet inhibitor in 207 helps provide a beautiful, long lasting finish when used with quality UV filtering varnish. 105/207 cures clear and colorless.

Mix Ratio, Resin:Hardener 3 parts resin : 1 part hardener

Pot life at 72°F (22°C) 20 to 26 minutes

Cure to a solid state 10 to 15 hours

Cure to maximum strength 4 to 7 days

Minimum recommended temperature 60°F (16°C)

Pumps 300, 306-23 or 309-3

Store at room temperature. Keep containers closed to prevent contamination. With proper storage, resin and hardeners should remain usable for many years. Over time, 105 Resin will thicken slightly and will therefore require extra care when mixing. Repeated freeze/thaw cycles during storage may cause crystallization of 105 Resin. Warm resin to 125°F and stir to dissolve crystals.

Hardeners may darken with age, but physical properties are not affected by color. After a long storage, verify the metering accuracy of the pumps and mix a small test batch to assure proper curing.

Tip: West System is a 2 part epoxy system that is measured by volume or weight. The volumes are NOT 50-50. We suggest you also purchase the set of 3 mini-pumps that will dispense the resin and hardener in the correct proportions. The upside to the pumps are they are very easy to use, the downside is they tend to dispense just a little more than you need. If you want to use small amounts, measure by volume using the weight ratio's listed on the containers.

Tip: Most epoxies can easily be colored by adding a drop or two of clothes dye. Start with just a drop or two. It doesn't take much.

Tip: Leave the mixing cup on the bench to cure right along with your knife. When checking the cure, check the mixing cup instead of the knife in case it hasn't set up yet. If you have a large cup full sitting to cure, be careful of heat this generates when curing. I have had a cup of this epoxy get so hot it scorched my plywood workbench top.